Description

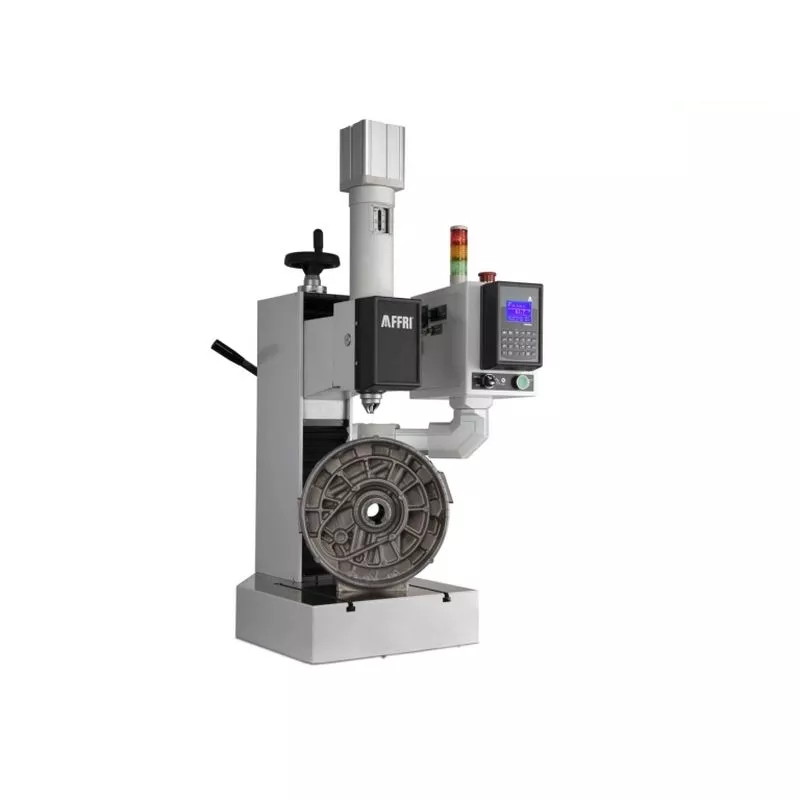

The RSD series semi-automatic hardness testers are designed for Rockwell, surface Rockwell, Brinell, and Vickers hardness testing in compliance with international ASTM and ISO standards.

These high-precision benchtop instruments are developed for industrial and laboratory applications, providing HBTW hardness values for Rockwell and Brinell scales with absolute accuracy (better than 0.5%) under any conditions. Their stable and precise readings from the very first test eliminate the need for repeated measurements.

The load system operates via a dynamometric load cell, completely removing the issues associated with traditional deadweight mechanisms — no alignment is required, they are vibration-resistant, and ensure accuracy regardless of position.

The testers feature a modern digital LCD display, intuitive user interface, real-time statistics, graphical data visualization, and large data storage for archiving results.

Suitable for hardness testing of all metals — cast iron, steel, hardened steel, brass, aluminum, copper, and alloys. Ideal for materials after heat treatment, hardening, nitriding, cementation, or surfacing.