Description

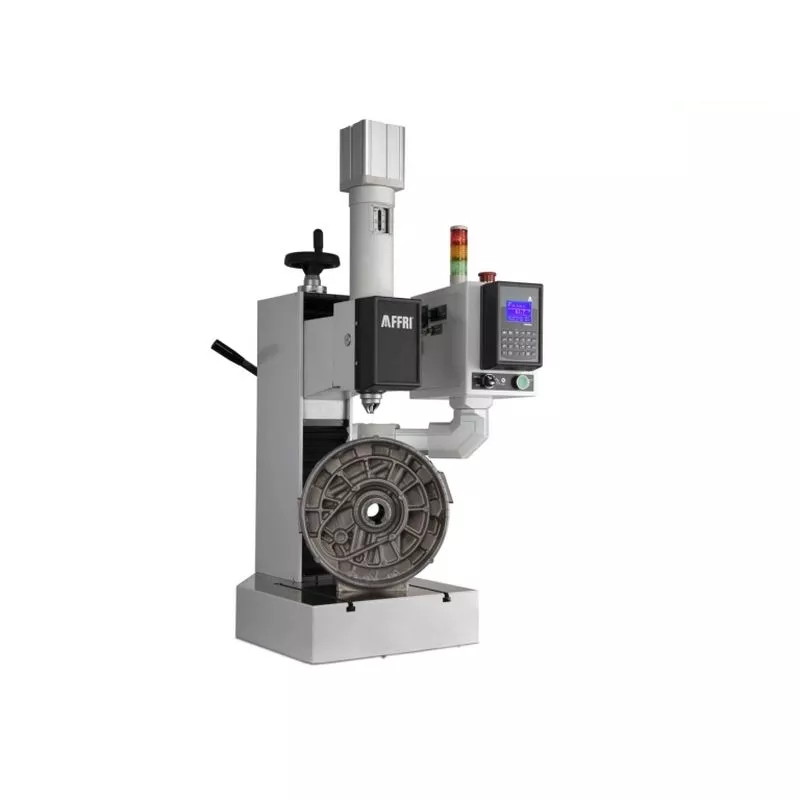

The Dakomaster 300 automatic hardness tester is designed for Rockwell, surface Rockwell, Brinell, Vickers, and Shore test methods in compliance with ASTM and ISO international standards. It is a high-precision desktop machine built for maximum performance in industrial and laboratory environments.

Equipped with a large touch screen, it allows intuitive operation, easy test planning, and clear visualization of results. Statistics, graphs, and reports are generated automatically and can be saved during the test session in an extensive data archive.

The interface includes conversion tables and an automatic correction function for tests on convex or cylindrical surfaces. The tester is fully motorized for completely automatic test cycles, featuring a long-stroke head and a large working base.

The load forces are applied through strain gauge sensors and controlled by closed-loop electronics (Afri patent), ensuring exceptional stability and accuracy.

Suitable for hardness testing of all types of metals — steel, cast iron, aluminum, brass, copper, and alloys — as well as for evaluating heat-treated materials (hardening, cementation, nitriding, surfacing). Also ideal for hard and soft plastics.