Description

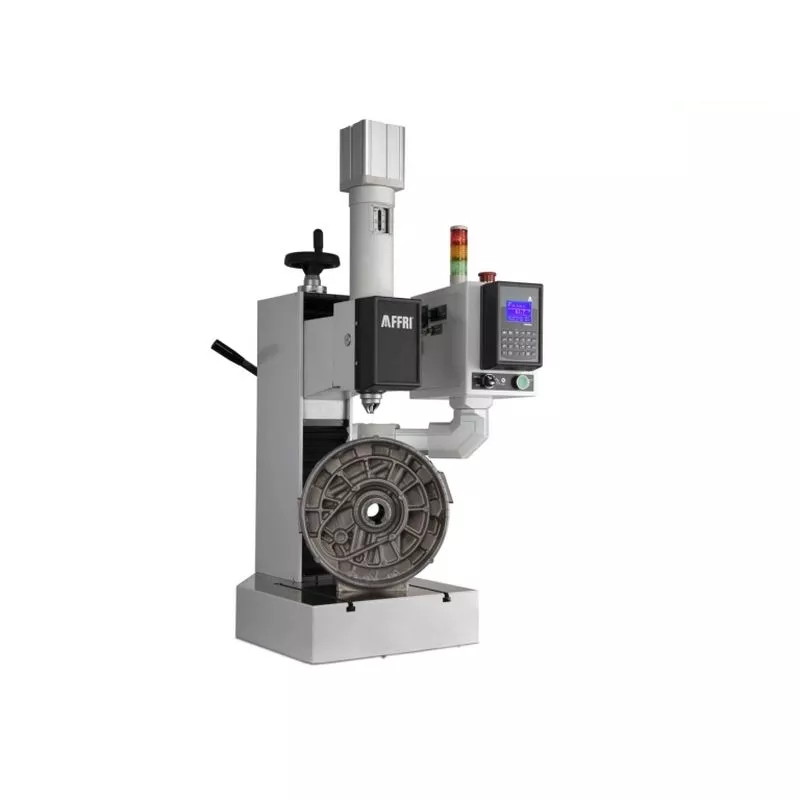

The Integral Revolver is an industrial hardness tester with reinforced construction, designed to accommodate two types of heads: an integrated milling head or a “Revolver” head with 8 stations. This configuration allows for the installation of different load cells and optical systems, resulting in a single versatile instrument capable of operating across the three main hardness scales — Brinell, Rockwell, and Vickers.

If the milling head is installed, the machine includes the same features as standard hardness testing heads: integrated surface cleaning, adjustable milling speed and depth, and fully automatic cycles. When equipped with the revolver head, integrated cleaning is not available, but the system supports all three hardness scales with dedicated load sensors and recognition optics.

The base plate in both configurations can be equipped with various clamping systems, including a T-slot plate, manual clamps, or hydraulic clamps for flexible and secure sample fixation.