Description

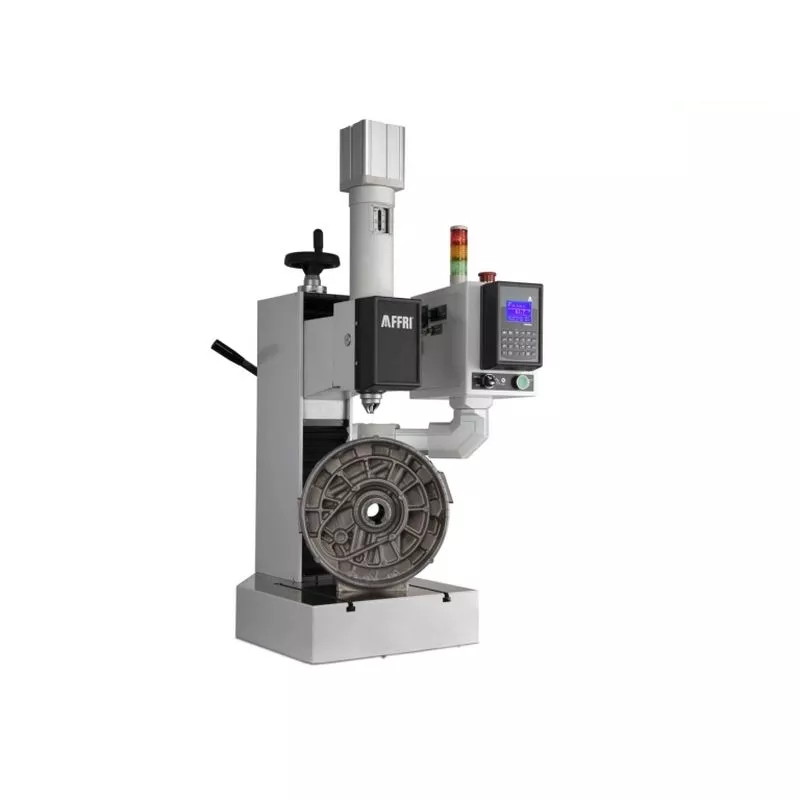

The DRM, EX, and RT semi-automatic hardness testers are designed for Rockwell, surface Rockwell, Brinell, and Vickers hardness testing in compliance with ASTM and ISO standards.

These compact benchtop instruments combine high precision and reliability with cost efficiency, making them ideal for both laboratory and industrial applications. To perform a test, simply bring the sample into contact with the indenter, pull the lever or press the button — the result appears within seconds.

The load application is managed through a weight sensor system that eliminates the limitations of traditional mechanical systems: the instruments are vibration-resistant, require no alignment, and can operate even at an angle. The ATI system applies the load directly along the indenter axis, without transmission levers, ensuring measurement stability and repeatability.

The DRM, EX, and RT series testers are suitable for testing all types of metals: cast iron, steel, hardened steel, brass, aluminum, copper, and alloys. Perfect for quality control after heat treatment, hardening, nitriding, cementation, or surfacing.