Description

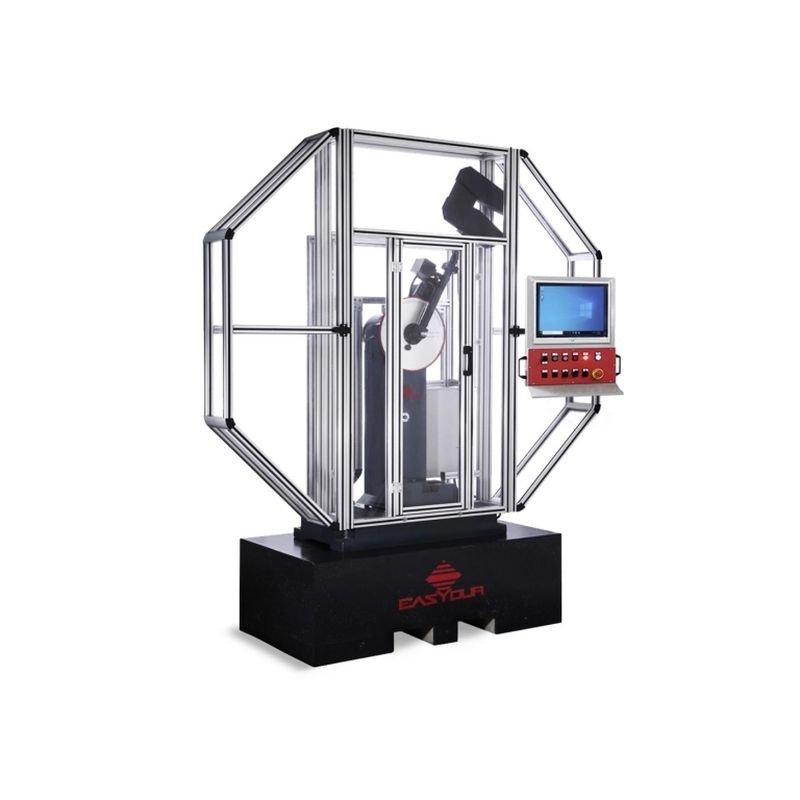

Broaching machine — a metal-cutting machine that allows making high-precision V- and U-shaped notches with a depth of 2, 3, or 5 mm on samples measuring 55 × 10 × 10 mm. At the end of the cycle, if necessary and in accordance with standard requirements, the machined samples have sharp or rounded notches required for proper fracture during the determination of KCU or KCV impact toughness, as provided by Charpy impact bending test standards.

The machine is equipped with a broach having calibrating teeth on the sides to remove the cut material (chips) from the sample. A hydraulic unit located above the traverse acts on the broach, pressing it vertically downward while the sample is held firmly by a vice at the base of the equipment.

Depending on the type of broach used, U- or V-shaped notches can be made to various depths (from 2 to 5 mm) in accordance with applicable standards.